The Product Requirements Document (PRD) is a familiar term to many engineers. We get this document from a product manager in one form or another, and it tells us what to build but not how to build it. But let’s face it, it’s probably better that way. We engineers hate being told how to implement an idea — that’s the fun part!

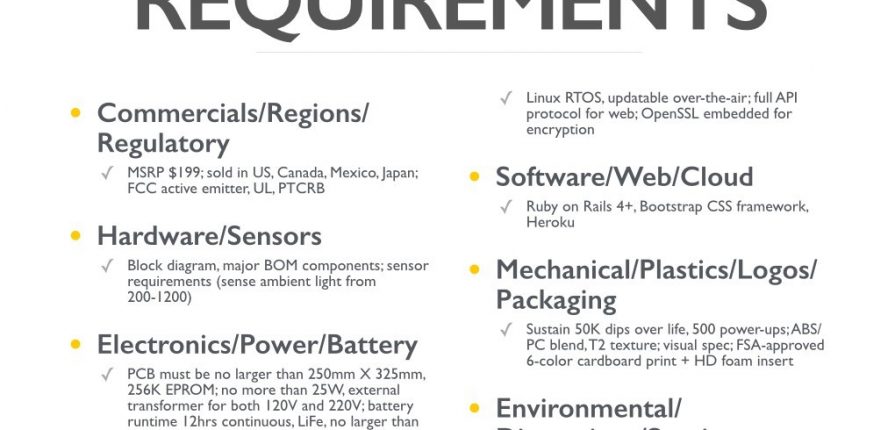

An Engineering Requirements Document specifies how a product will be built in order to fulfill the PRD’s multitude of wishes. The effort of writing this document is usually led by a system architect or engineering lead, but it’s essential that engineers from all disciplines (mechanical, electrical, firmware) contribute.

Why Should I Write an ERD?

First of all, writing an ERD enables collaboration. It helps to break down a large project into smaller tasks so you can then delegate out the tasks to team members, giving everyone a clear area of responsibility. Comparatively isolated modules can be outsourced if internal resources are constrained.

Writing an ERD can also reduce miscommunication between product, design, and engineering teams. The ERD results from interpreting the PRD, and some assumptions will be made during the writing process. After a draft has been written, the product and design teams can read the ERD and check those assumptions, ensuring product and design intent are sufficiently captured.

Lastly, writing the ERD is the first step in establishing a sound test plan. Any performance requirements listed in the ERD need corresponding tests to verify them. Why require something if it cannot or will not be tested?

3 Step Approach

1. Translate the features and performance requirements described in the PRD to engineering specifications

Let’s start with an example product: a portable, wireless speaker.

The PRD calls for 7 days of battery life. This spec needs to be translated into battery capacity (in amp-hours). In order to do this, the electrical engineers probably need to make a power budget, and ask questions like “what is the active and inactive/standby time that make up 7 days?”. Both engineering and product need to agree on that answer.

Based on charging or replacement requirements, you can narrow down the type of battery you’d like to use. With this additional constraint, battery capacity translates well into standard sizes or volume (in the case of Li-Po), useful information for mechanical engineers.

The PRD also says that the speakers should be bass-heavy. To an audio engineer, this translates to a set of frequency response graphs with certain shape—these graphs will be the engineering specification. The DAC (digital-analog converter) and mechanical enclosure both have impact on the frequency response and they will be designed to meet the audio specification.

2. Identify cross functional dependencies

The previous example showed that achieving each product feature involves the collaboration of multiple disciplines; the ERD should document how mechanical and electrical components work together.

Take our speaker for example again: there are buttons to control volume. A mechanical engineer will design the physical buttons, choose the switches underneath, decide how to mount the switch PCBAs, and give an electrical engineer the PCB footprint and switch pad locations so he can do the schematics and layout. The ERD should capture the division of responsibility for each feature of the product.

3. Mechanical engineering special: translate the industrial design spec into ME language

Mechanical or product design engineers not only need to fulfill the PRD’s requests, but also make the industrial designers happy. Tough job indeed!

The industrial design spec usually comes in the form of a surface CAD model and a CMF (color, material, finish) document. The surface model needs to be converted to a solid CAD model, and the CMF document needs to be translated into a mechanical engineering spec.

Color

Has the industrial designer called out a Pantone number? A Pantone plastic number is great, but a lot of Chinese plastics vendors don’t even own the $2000 plastics catalogue, and you will still have to provide the sample chip. Usually, it’s sufficient to have a Pantone Coated number and do any fine-tuning at the time of injection.

White is notoriously hard to get right, and Pantone C is not suitable for communicating exactly what kind of white you want. The easiest thing to do here is to provide an actual plastic swatch — it doesn’t have to be Pantone, just an example from another product you like.

Also note that sometimes in-mold coloring won’t achieve the aesthetic quality required by the industrial designers. It’s up to the mechanical engineer to determine whether painting is more suitable.

Material

If the industrial designer has called out plastic, it’s up to you, the mechanical engineer, to choose the resin. Durability and performance characteristics from the PRD will inform the choice.

If metal shows up in the design, it’s important to really understand the industrial designer’s intentions. Sometimes we can get away with metallic vapor deposition over plastic to achieve a metal appearance, or using sheet metal trim over plastic structure. However, if solid metal components are called for (often to suggest higher quality), we have to determine whether to use casting, CNC machining, or metal injection molding to produce the parts.

Finish

The texture of the product enclosure can be achieved in a multitude of ways. Specific painting, blasting, brushing, and polishing techniques can be worked out with the contract manufacturer at a later stage. If the plastic parts require texturing, in-mold is a good way to go. You, the engineer, can ask the industrial designer to choose a swatch out of a Mold-tech or Yick Sang texture catalogue and give this number to the mold maker.

PRD to ERD Translation Table

The table below translates some common PRD requirements into ERD requirements.

Main Takeaways

Writing an ERD is a great first step for kicking off the engineering process of any product, especially if there are a lot of moving pieces, and many engineers need to work together.

An ERD is a living document in the early days of product development. You can begin by writing a high-level ERD consisting of requirements, and fill in the details as more decisions are made, like what chips to use.

When you’re ready to engage contract manufacturers, you’ll thank yourself for having written a great ERD. There is no better way to impress a manufacturer than presenting both the PRD and the ERD when you request a quote.

Remember, the better they can understand your product, the better they’ll build it.